Supply Chain Management

What are the key challenges and strategies for success in the manufacturing industry?

In manufacturing, the biggest challenges include workforce shortages of qualified skilled workers, employee retention issues, and adapting to new technologies. For success, businesses should focus on efficiency, automation, and supply chain resilience. While pay is important for retention, workplace culture also matters greatly - employees need to feel appreciated and have flexible schedules. Lean manufacturing principles like value stream mapping and waste elimination remain crucial. Digital tools such as AI, Internet of Things, and predictive maintenance can help anticipate equipment needs and streamline operations. Companies must overcome resistance to change while creating supportive work environments that still maintain productivity.

Watch clip answer (03:52m)What are the key changes shaping procurement as we head into 2025?

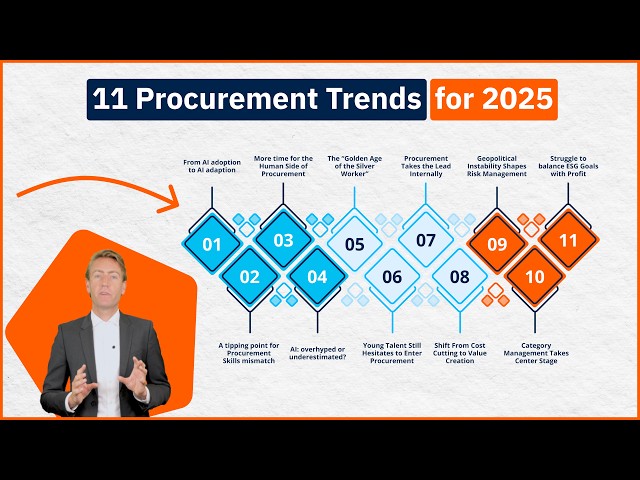

As procurement approaches 2025, three significant changes are transforming the field: AI integration, workforce demographics, and evolving focus. AI will revolutionize operations but requires careful management of privacy concerns and skill gaps. Meanwhile, the workforce is shifting as experienced professionals retire while younger talent remains hesitant to enter procurement, forcing teams to rethink talent strategies. Procurement's focus is also evolving from traditional cost-cutting to value creation, risk management, and sustainability. By embracing these trends as opportunities rather than challenges, professionals can achieve better outcomes for their teams and organizations in this changing landscape.

Watch clip answer (00:44m)How do tariffs affect Sandra Payne's concrete equipment business?

Tariffs affect every aspect of Sandra Payne's business since her company relies heavily on imported materials like steel, aluminum, bearings, hose, and wire that are no longer sourced domestically. These tariffs create delays in receiving materials and increase costs that must eventually be passed on to customers. The impact extends beyond her business to the entire construction supply chain, affecting civil and large commercial projects, ultimately hurting everyone in the industry. As Sandra notes, she has little control over where materials originate, but must pay the higher prices regardless.

Watch clip answer (01:40m)How is sustainability becoming a driver of change in global supply chains?

Sustainability has evolved from a corporate value into a significant driver of operational change across global supply chains. Companies like 3M have implemented zero landfill waste in 30% of their manufacturing plants worldwide, while focusing on dematerializing production and creating a more circular economy. According to survey data, 18% of businesses are already changing their supply chains specifically for sustainability reasons, with this percentage expected to grow. This transformation extends throughout the entire supply chain - from production plants to refrigeration techniques, warehousing, and logistics. As consumer markets expand, particularly in Asia where growth remains strong at 4-6%, sustainability considerations are becoming a critical criterion for future business operations.

Watch clip answer (02:45m)How is China affecting the global lithium supply chain?

A Chinese firm has suspended exports of key filtration equipment essential for lithium processing, signaling the early impact of Beijing's proposed export controls. This development represents a significant disruption to the global lithium supply chain, as these filtration systems are crucial components in the production process of lithium, which is vital for batteries and modern technology manufacturing. This move appears to be part of a broader strategy by China to exert control over critical mineral processing technologies, potentially affecting industries worldwide that rely on lithium for clean energy and electronic products.

Watch clip answer (00:08m)What action has a Chinese firm taken regarding lithium processing equipment?

A Chinese firm has implemented export controls on key filtration equipment used in lithium processing. This move represents the early impact of Beijing's proposed export control policies, suggesting a shift in China's approach to managing strategic resources and technologies. The restriction on this critical equipment could potentially disrupt global lithium supply chains, which are essential for industries like electric vehicles and renewable energy storage. This development signals China's increasing use of trade policy as a geopolitical tool amid rising international tensions.

Watch clip answer (00:08m)