Engineering

Engineering is the disciplined application of scientific and mathematical principles to design, create, and optimize structures, systems, and processes. Spanning a multitude of specialized fields such as mechanical engineering, civil engineering, electrical engineering, and software engineering, this profession is integral to addressing complex technological challenges and enhancing quality of life across global populations. The role of engineers is evolving rapidly, with a significant emphasis on sustainability and innovation, catalyzed by developments in artificial intelligence (AI), robotics, and advanced materials. Reports highlight that, currently, 90% of engineering teams are integrating AI tools into their workflows, reflecting a transformative shift in how engineering tasks are approached and executed. As industries increasingly prioritize efficiency and sustainability, engineers are tasked with pioneering solutions that incorporate cutting-edge technologies. From advanced design systems that leverage generative design software to the development of self-healing materials and autonomous systems, engineering practices are becoming more interdisciplinary. This synergy not only fosters creativity but also accelerates product development and enhances the potential for creating environmentally responsible infrastructures. Recent statistics from the U.S. Bureau of Labor indicate a robust growth trajectory in engineering roles, with projections estimating around 200,000 new positions annually arising from technological advances and the need for skilled workers in key areas like renewable energy and cybersecurity. In this evolving landscape, engineering continues to be at the forefront of shaping a sustainable and technologically-enhanced future.

What are the main components of a gas turbine engine and what makes the high pressure turbine critical?

A gas turbine engine consists of four main sections: the fan, compressor, combustor, and turbine. Air is compressed through the fan and compressor, then enters the combustor with fuel, creating high pressure, high temperature gases that flow into the high pressure turbine. This turbine section is the most critical part of the engine because it operates in extreme conditions, with gases reaching about 1,500°C, often in corrosive environments like salt air. The high pressure turbine must withstand these harsh conditions while ensuring flight safety, making material selection particularly important for this component.

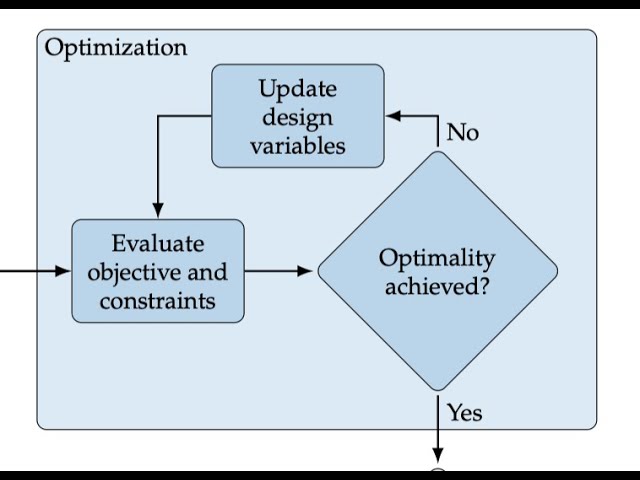

Watch clip answer (05:48m)What is the difference between a typical design process and an optimization process?

A typical design process involves reevaluating and making changes until you're satisfied, but it's not an optimization process. In optimization, we first formulate a specific problem with defined objectives and constraints. The computer then automatically evaluates these objectives, checks if optimality criteria have been met, and updates design variables accordingly. This automated process continues, potentially thousands of times, until optimality criteria are achieved, rather than stopping when the designer is satisfied or tired of making changes.

Watch clip answer (01:18m)What are the key features and design elements of India's Tejas Fighter Jet?

The Tejas fighter jet features a lightweight yet robust design with 45% of its airframe made from advanced materials including carbon fiber reinforced polymer and grade 5 titanium alloys. It incorporates stealth features through radar-absorbing indium oxide coating and has a modular design allowing engine flexibility. The aircraft boasts impressive capabilities including a 6,500kg payload capacity, 3500km range, and advanced avionics such as an integrated infrared search and track system. Its digital fly-by-wire controls include disorientation recovery for enhanced safety. The Tejas also features a sophisticated radar system capable of tracking 50 aircraft at 150km and engaging four simultaneously, all while maintaining remarkable cost-effectiveness at under $45 million.

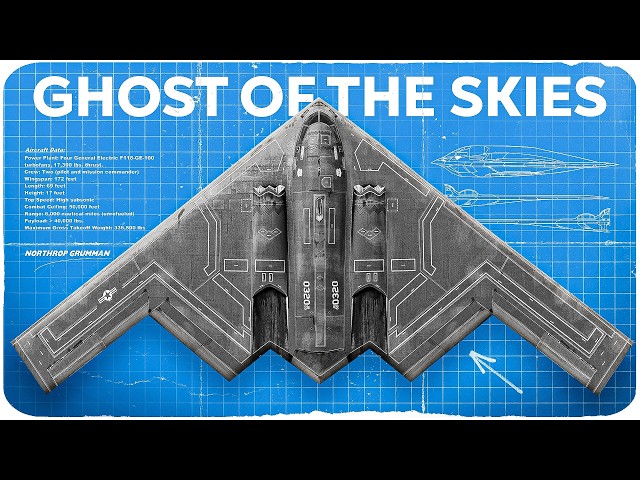

Watch clip answer (05:08m)How does the B2 Spirit achieve its stealth capabilities?

The B2 Spirit achieves its stealth capabilities through multiple advanced techniques. Its unique flying wing shape with smooth panels and minimal seams creates an exceptionally low radar cross section, providing aerodynamic efficiency while minimizing radar reflection. The aircraft's exterior is coated with classified radar-absorbent materials that absorb radar energy rather than reflecting it back to detection systems. Additionally, the B2 conceals its engines by burying them deep within the aircraft's body with intakes hidden on top of the wing, preventing radar waves from bouncing off engine fan blades. Its exhaust is cooled and spread across a wide area to reduce infrared signature. These innovations, combined with sophisticated electronic countermeasures, result in a bomber with a radar cross section approximately 1,000 times smaller than a conventional B-52, making it virtually invisible to enemy detection systems.

Watch clip answer (03:33m)What makes bamboo crash barriers more sustainable than traditional steel barriers?

Bamboo crash barriers boast a recycling value of 50-70%, significantly higher than traditional steel barriers which only range from 30-50%. The bamboo species used undergoes specialized treatment for enhanced strength and durability, making it not only environmentally friendly but also cost-effective. By offering a greener alternative to steel, these bamboo barriers are setting new standards for road safety infrastructure. This innovative approach combines sustainability with practical functionality, demonstrating how natural materials can be effectively utilized in modern construction applications.

Watch clip answer (00:33m)What is India's innovative bamboo crash barrier and what are its key features?

In March 2023, India introduced the world's first 200-meter long bamboo crash barrier on Maharashtra's Bahubali highway, representing a groundbreaking advancement in road safety. The innovative structure underwent rigorous testing at premier research facilities, including the National Automotive Test Tracks in Indore, where it earned top fire safety ratings and demonstrated impressive resilience against high-impact situations. Made from specially treated bamboo, the barrier offers exceptional durability while providing an environmentally friendly alternative to traditional steel barriers. This sustainable innovation maintains strength and safety while contributing to greener infrastructure solutions.

Watch clip answer (00:26m)